Maqhubu a turbine a tloaelo a superalloy turbine

Lehare la turbine ea khase

Khampani e na le sehlopha sa taolo ea boleng bo botle, theknoloji e ntle haholo ea tlhahlobo, lisebelisoa tse tsoetseng pele tsa tlhahiso le lisebelisoa tsa tlhahlobo le sehlopha se ruileng se nang le boiphihlelo.Khampani e na le botumo bo botle 'me e na le tšebelisano e ntle ea nako e telele le bahlahisi ba tsebahalang lapeng le linaheng tse ling.

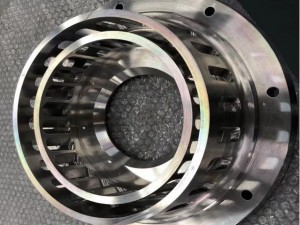

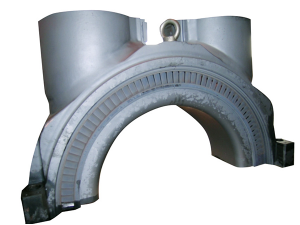

Likarolo tsa mantlha tsa mahare a turbine ea khase ke:

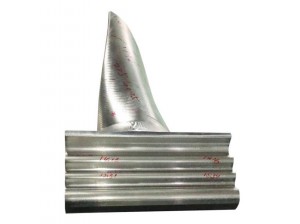

1. Thepa e na le lintho tse turang tsa superalloy;

2. Ts'ebetso e mpe ea ts'ebetso;

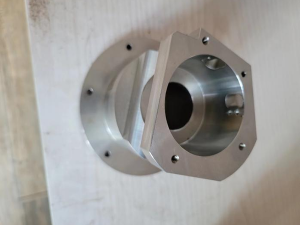

3. Sebopeho se rarahaneng, ho nepahala ho phahameng le litlhoko tsa boleng bo holimo;

4. Ho na le mefuta e mengata le bongata;

Litšobotsi tse ka holimo tsa li-blades li khetholla tataiso ea nts'etsopele ea ts'ebetso ea lehare le tlhahiso: hlophisa tlhahiso e khethehileng;Ts'ebetso e tsoetseng pele e se nang letho e nang le seha se senyenyane kapa e se nang letho e amoheloa ho ntlafatsa boleng ba sehlahisoa le ho boloka thepa e hanyetsanang le mocheso o phahameng;Adopt lisebelisoa tsa mochini o ikemetseng le oa othomathike, hlophisa mela ea tlhahiso ea othomathike bakeng sa tlhahiso ea phallo, 'me butle-butle u nke taolo ea lipalo le theknoloji ea khomphutha bakeng sa ts'ebetso.

Joalokaha bohle re tseba, li-blades ka li-turbine tsa khase ke "pelo" ea turbomachinery le likarolo tsa bohlokoa ka ho fetisisa ho turbomachinery.Turbine ke mofuta oa mochini o potolohang oa matla a mokelikeli, oo ka kotloloho o bapalang karolo ea ho fetola matla a mocheso a mouoane kapa khase hore e be matla a mochini.Hangata li-blades li sebetsa tlas'a mocheso o phahameng, khatello e phahameng le sebaka se senyang.Li-blades tse tsamaeang li boetse li potoloha ka lebelo le phahameng.Ka har'a li-turbine tse kholo tsa mouoane, lebelo le holimo la lehare le feta 600m/s, kahoo lehare le boetse le na le khatello e kholo ea centrifugal.Palo ea li-blades ha e kholo feela, empa hape sebopeho se rarahane, 'me litlhoko tsa ho sebetsa li thata;Mosebetsi oa ho sebetsa oa li-blades o moholo haholo, o nka kotara ho isa ho karolo ea boraro ea kakaretso ea matla a ho sebetsa a li-turbine tsa mouoane le li-turbine tsa khase.The

machining boleng ba di-blades ama ka ho toba tshebetso bokgoni le ho tšepahala ha yuniti, 'me boleng le bophelo ba di-blades li amana haufi-ufi le machining mokhoa oa di-blades.Ka hona, mokhoa oa ho sebetsana le lehare o na le tšusumetso e kholo ho boleng ba ho sebetsa le moruo oa tlhahiso ea mechine ea turbine.

Khamphani ea rona ke moetsi ea hloahloa oa li-blades, 'me e na le litsi tse tharo tsa machining tse tsoang kantle ho naha, litsi tse 'ne tse tsoang kantle ho naha tse hlano tse tsoang kantle ho naha, lisebelisoa tse 'ne tsa othomathike tsa CNC, li-detectors tse tharo tsa Hikscon, li-scanner tsa GOM le lisebelisoa tse' maloa tse thusang.Khampani e na le sehlopha se matla sa tekheniki se nang le boiphihlelo bo bongata boqaping ba li-blade, boenjiniere ba reverse, mohlala, mananeo le ts'ebetso ea morao-rao.

Ho na le mefuta e mengata ea li-blades, empa mefuta eohle ea li-blades e entsoe ka likarolo tse peli tse kholo, e leng karolo ea karolo ea mouoane le karolo ea bokaholimo ba kopano.Ka hona, ts'ebetso ea lehare e boetse e arotsoe ka ts'ebetso ea sebaka sa kopano le ts'ebetso ea tsela ea mouoane.Karolo ea bokaholimo ba kopano e boetse e bitsoa karolo ea motso oa lehare E nolofalletsa lehare hore le behoe holim'a impeller ka mokhoa o sireletsehileng, ka botšepehi, ka nepo le ka mokhoa o utloahalang ho netefatsa ts'ebetso e tloaelehileng ea tsela ea mouoane.Ka hona, sebopeho le ho nepahala ha karolo ea kopano li tla khethoa ho ea ka mosebetsi, boholo, litlhoko tse nepahetseng tsa karolo ea karolo ea mouoane le mofuta le boholo ba khatello ea kelello.Kaha mesebetsi, litekanyo, liforomo le mosebetsi oa likarolo tse fapaneng tsa blade steam passage li fapane, ho na le mefuta e mengata ea meaho ea likarolo tsa kopano.Ka linako tse ling, ka lebaka la litlhoko tsa ho tiisa, ho feto-fetoha ha maqhubu, ho fokotsa ho sisinyeha le khatello ea kelello, lehare hangata le na le lesela (kapa lesela) le thae bar (kapa damping boss).Li-shrouds le li-braces li ka boela tsa hlalosoa e le libaka tsa kopano.Karolo ea karolo ea mouoane e boetse e bitsoa karolo ea profil, e etsang mocha oa phallo ea moea e sebetsang 'me e phethela karolo eo lehare le lokelang ho e bapala.Ka hona, boleng ba ts'ebetso ea karolo ea karolo ea mouoane bo ama ka ho toba katleho ea yuniti.